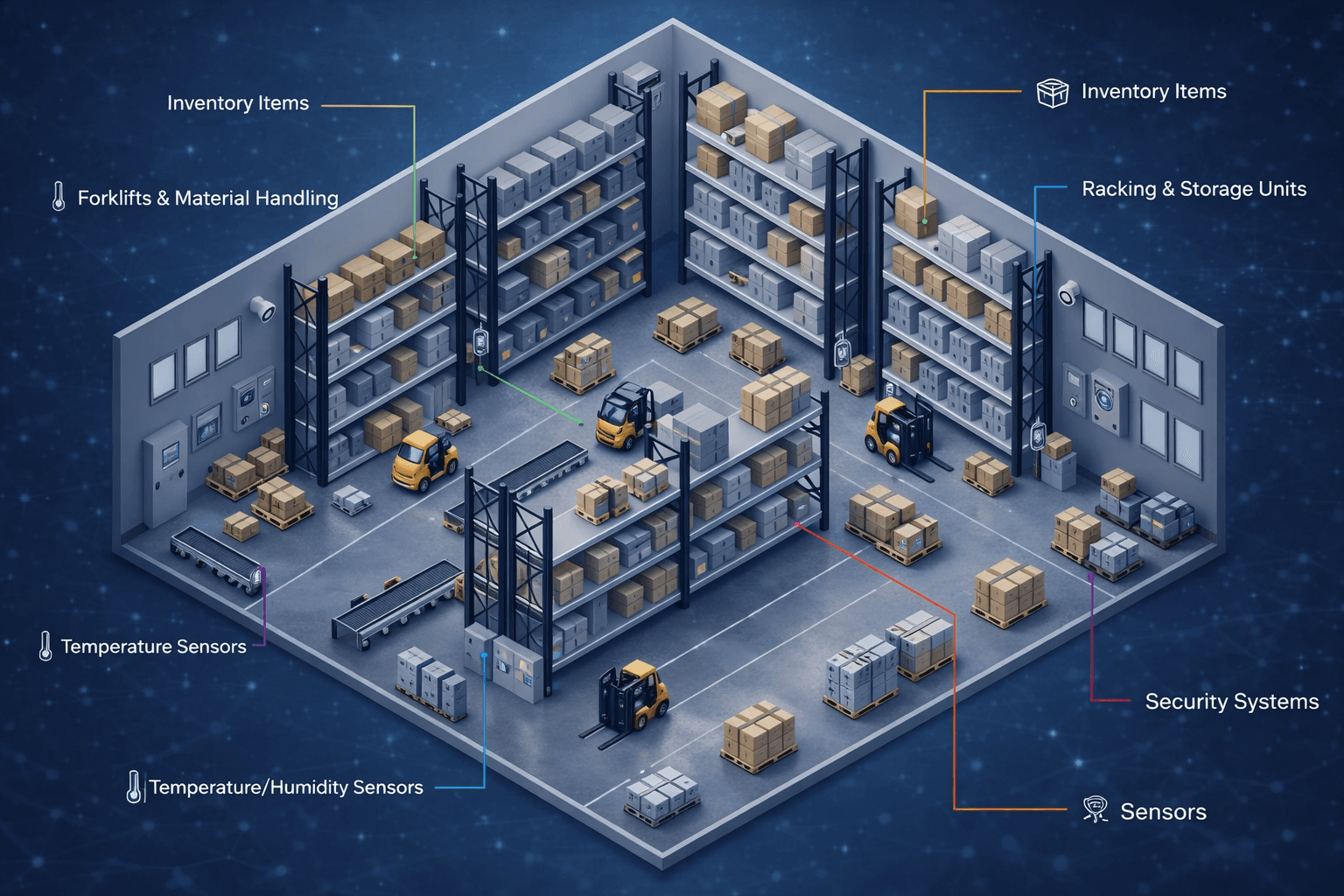

Mendygo’s Warehouse Management System (WMS) provides end-to-end visibility, control, and optimization of warehouse operations. From real-time inventory tracking to AI-driven space and workflow management, the solution ensures operational efficiency, reduced errors, and optimized resource utilization.

Our modular approach allows you to choose the specific solutions you need, creating a customized system that fits your unique requirements.

Monitor stock levels, expiry dates, and batch/lot numbers

Track inbound/outbound goods and automate replenishments

Alerts for low stock, damaged goods, or misplaced items

Track forklift, conveyor, and automated guided vehicle (AGV) usage

Monitor equipment health, fuel/energy consumption, and maintenance needs

Optimize equipment scheduling to minimize idle time

Map warehouse zones digitally for better inventory placement

AI-driven recommendations for maximizing storage efficiency

Optimize picking routes to reduce travel time

Real-time picking, packing, and shipping status

Integration with ERP and transport systems for seamless operations

Automated reporting for timely order completion and audits

Monitor environmental conditions (temperature, humidity) for sensitive goods

Track adherence to safety standards and SOPs

Alerts for unauthorized access or equipment misuse

Download the complete product brochure to explore system capabilities, architecture, integrations, and deployment models.

Detailed documentation covering features, system design, scalability, and real-world use cases.

Schedule a personalized demo and see how Mendygo’s management systems deliver automation, visibility, and control.